Special corrosion-resistant coating for ramming piles

Cost-saving, sustainable and reduced emissions

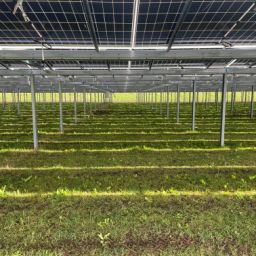

An important innovation is available for steel processing companies installing structures in corrosive environments. After extensive test productions, Magnelis ZM800 is being delivered in series production for the first time. This is the ideal steel grade for the production of fencing, solar panel mounting systems and marine structures.

KS Service Center is part of the KS Industries group and is the first supplier in the world to process and supply the new steel grade. KS Systems is gratefully taking advantage of this opportunity for complete system solutions.

Cost savings and warranty

This new Zinc Magnesium steel grade is very cost-effective. It is a significantly cheaper alternative to traditional aluminum or traditional hot dipped galvanized steel . This is labor intensive and nowadays very expensive due to energy prices. Zinc-coated steel can be used without additional post treatment . It offers our clients up to 25 years warranty against corrosion. In addition, ZM800 is produced with significantly less greenhouse gas emissions.

Steel with security

By guaranteeing up to 25 years against corrosion, you can offer investors more security on their projects. As a result, banks are more willing to lend to investors. In addition, the durability of this steel ensures that maintenance costs are substantially lower.

Properties and applications

Magnelis ZM800 has a zinc aluminum magnesium coating of as much as 800 grams per m2 for the total of both sides. This means a thickness of 65 µm per side. A zinc aluminum magnesium coating of 800 grams is unique in the world of zinc magnesium coatings, according to the steel producer. The thickest known zinc coating to date is 620 grams per m2. ZM800 is at least as corrosion-resistant as piece galvanized (post-galvanized) and a good alternative to aluminum.

Want to know more about technical details or have concrete interest? Get in contact with us.

Vul hier uw eigen inhoud in.

.jpg?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=5b8691a22ed731f1e7d863901f4b342c75fa2c66)

.jpeg?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=f0c3e87de36c529501ce941b5c954e1d7b6373da)

%20-%20Z9-14-Edit%20kopie%CC%88ren.jpg?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=21a563ec612ffcd7e853e57c02369a69e8dfb0cf)

.jpeg?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=bfe407ca204238f7a78550b246979e7004b3e962)

.jpg?width=256&format=jpeg&dpr=1.0&signature=d0c79bb2859051748b8f93bc65ffac3a5e1d1ae5)